Once upon a time, a substandard paint job was difficult to prove. However, there’s now a way for the yachting industry to objectively measure (and ultimately control) surface texture; a major contributor to how a painted surface is perceived. Here, Joop Ellenbroek explains why now is the time to turn to wavescan technology for the perfect finish.

What is wavescan technology?

It all comes down to the finish. A high quality paint finish is described by its brilliance and smoothness, often referred to as DOI (Distinctness of Image). However, while paint technology has delivered very high gloss liquid coatings, there are still problems controlling waviness in the final surface appearance of paint finishes.

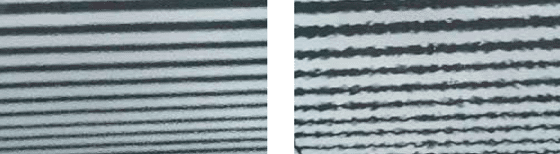

When a paint job results in a wavy, light-and-dark pattern hiding somewhere in the paint, it is bad news. The so-called “orange peel” finish is unsightly and costly and time-consuming to fix, especially if the product gets all the way to the owner before being noticed. However, until recently there were no instruments available for objectively measuring the surface texture. It all came down to individual opinion, which could often lead to disputes.

That’s where the wave-scan technology comes in. It offers a way to objectively control, measure and optimise the appearance of the surface texture. In the automotive industry, manufacturers have been able to use wavescan equipment to ultimately improve the topcoat surface of car paint jobs, by establishing processes that can quantify and qualify the topcoat appearance. Even aircraft makers such as Boeing are using wavescan. Now, the same advantages can be enjoyed in the yachting industry to ensure a flawless finish.

Measuring surface texture using wavescan equipment

The surface texture of a paint surface comprises a mixture of various textures, ranging from very fine to very course. Each texture contributes to the overall visual perception of the painted surface.

The distribution of these textures depends on many factors, such as product type, product quality, conditions during application, and drying and quality of application. The application process must accommodate varying contours and orientation – straight, curved, horizontal and vertical. Despite what many people think, there is no correlation between gloss and DOI. A surface with poor DOI can return excellent gloss measurement results.

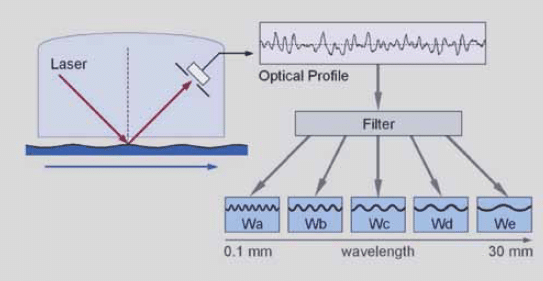

Wavescan equipment measures the ship’s painted surface and categorizes the readings in to wavelength bands.

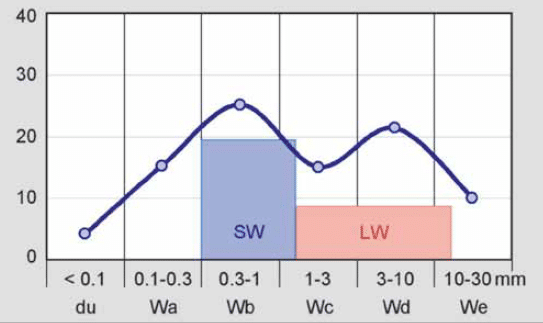

The wavescan equipment uses a laser beam to detect the different types of surface texture. Measurements of waviness are automatically correlated in mathematical terms according to other industry-wide visual measurement scales including tension value and orange peel standard ranking. The surface textures are differentiated into six categories, identified by wavelength.

What do the measurements mean?

The distribution of the surface textures (expressed as wavelengths) can be visualised in a graph. The surface textures are divided into a short wave and a long wave range; short wave for the perception at short distance and long wave for the perception at long distance. Short wave is the value that causes the most noticeable orange peel.

The long and short wave values are expressed in figures from zero and above. Low short wave values mean that there is low disturbance of the visual appearance at a longer viewing distance. Low long wave values means that the appearance is hardly disturbed when viewed from a distance; in other words, the lower, the better.

On the surface

There are other factors in addition to gloss and DOI that impact how topcoat quality is perceived. One of the major factors is Haze. Surface haze can be a problem in high gloss coatings, such as those found on superyachts. It comes down to a number of causes including incompatible materials in a formulation, difficulties in application and problems encountered during drying and curing. Haze is also associated with polishing and buffing. Coatings without haze appear to have a deep reflection and a highly reflective contrast. Those with a lower level of reflection haze, on the other hand, exhibit a somewhat milky finish on the surface. With a high haze, the reflection of a strong light source will result in the image blooming with a bright halo.

Getting the perfect finish

By detecting and measuring orange peel in yacht finishes, wavescan technology helps to ensure orange peel problems do not reach the final customer, so that they get the look and finish they desire. Shipyards can use the technology to determine their own performance, while yacht owner and their crew can also use the technology to determine whether the topcoat surface of their new yacht meets their standards. If not, they can hold their shipyards accountable by simply showing them the objective data.

Wavescan technology is setting the benchmark for high quality paint finishes throughout the vehicle industry, and it’s time for the yacht industry to reap the rewards. CCS Yacht Coating Services is at the forefront of Wavescan technology having invested in high cost equipment and training. CCS can support shipyards and superyacht owners with their wavescan equipment and expertise on how to utilise this in a superyacht environment.

For more information please contact

| Paul J. Bournas +31 (0) 630123240 paul@ccsyacht.com |